Discovering the Crucial Applications and Utilizes of Aluminum Shop in Modern Manufacturing

Aluminum foundries play an important role in contemporary manufacturing, offering diverse sectors with their one-of-a-kind residential or commercial properties. From automotive parts that improve fuel performance to aerospace structures that focus on weight, aluminum's versatility appears. Its applications extend to building and construction and consumer electronics, highlighting its resilience and power efficiency. The advancements in aluminum spreading techniques and future trends call for a closer examination, as they may redefine its effect on manufacturing.

The Function of Light Weight Aluminum Foundries in Automotive Production

As the automobile market significantly prioritizes light-weight products to boost fuel effectiveness and performance, light weight aluminum foundries have ended up being crucial contributors to manufacturing processes. These foundries focus on creating elements that fulfill the rigorous needs of modern cars, such as engine blocks, transmission housings, and architectural aspects. Light weight aluminum's beneficial residential or commercial properties-- such as high strength-to-weight proportion, corrosion resistance, and outstanding thermal conductivity-- make it a suitable option for vehicle applications.

Moreover, aluminum shops make use of advanced casting methods, consisting of die spreading and sand casting, to produce elaborate and resilient parts. This capacity allows suppliers to enhance styles for efficiency while minimizing weight. Using aluminum likewise supports sustainability goals, as it is highly recyclable and reduces power intake in automobiles. By facilitating the assimilation of aluminum into automotive layout, foundries play an essential duty fit the future of the automobile industry, promoting efficiency and development throughout the board.

Aerospace Applications: Lightweight Solutions for Trip

Aluminum shops play a considerable duty in the aerospace field, where the need for light-weight materials is paramount for improving gas effectiveness and efficiency in airplane. The one-of-a-kind properties of light weight aluminum, including its high strength-to-weight ratio and rust resistance, make it a suitable choice for various aerospace parts. These components consist of structural components, engine coverings, and touchdown equipment, which contribute to overall aircraft performance.

Using aluminum alloys, particularly those created with sophisticated spreading methods, enables the manufacturing of detailed layouts and complicated shapes while reducing weight. In addition, aluminum's recyclability lines up with the aerospace sector's sustainability goals, reducing environmental impact. With constant improvements in aluminum shop technologies, makers can enhance production processes, resulting in boosted performance and reduced costs. As the aerospace industry increasingly focuses on innovations that boost performance, light weight aluminum factories will remain indispensable to establishing lightweight options for contemporary flight.

Structure and Construction: Enhancing Structural Integrity

In the structure and building sector, a substantial emphasis is positioned on boosting structural honesty with making use of aluminum. Known for its high strength-to-weight proportion, aluminum supplies toughness without endangering on weight, which is crucial in modern-day building styles. Its resistance to corrosion even more ensures durability, making it a suitable material for numerous structural components, consisting of beams, frameworks, and cladding.

Aluminum likewise facilitates cutting-edge design opportunities, allowing engineers and engineers to create visually pleasing frameworks while preserving safety and security standards. The product's flexibility allows its application in both residential and business tasks, from skyscrapers to bridges. In addition, improvements in light weight aluminum foundry methods have actually boosted the precision of light weight aluminum parts, guaranteeing they meet rigid building ordinance. Overall, the combination of light weight aluminum in building and construction not just enhances structural stability yet additionally adds to sustainable building methods, provided its recyclability and energy-efficient manufacturing approaches.

Customer Electronic Devices: The Rise of Aluminum in Technology

In the domain of customer electronic devices, light weight aluminum has actually gotten prestige due to its lightweight design advantages and premium thermal conductivity. This shift not just enhances product portability however likewise enhances gadget efficiency by properly dissipating warmth. As modern technology remains to develop, the duty of aluminum in creating effective and streamlined devices is progressively substantial.

Lightweight Style Benefits

As consumer electronic devices advance, the need for light-weight yet sturdy products has surged, making aluminum a significantly popular option amongst suppliers. Its reduced density enables the development of smooth gadgets that are simple to bring and make use of, considerably improving transportability. The strength-to-weight ratio of aluminum guarantees that items can withstand daily wear and tear without endangering efficiency. Additionally, the malleability of light weight aluminum enables makers to design elaborate shapes and forms, further contributing to innovative aesthetic appeals and performance. This lightweight characteristic additionally plays an important duty in energy effectiveness, as lighter tools need much less power to operate. Consequently, aluminum not just fulfills the progressing visual demands however additionally aligns with the contemporary concentrate on sustainability in consumer electronics.

Thermal Conductivity Perks

Thermal conductivity is a crucial consider the performance of consumer electronics, and light weight aluminum master this domain. Its high thermal conductivity permits reliable warmth dissipation, which is necessary for maintaining optimal operating temperatures in gadgets such as smart devices, laptops, and video gaming consoles. By facilitating rapid warm move far from sensitive elements, aluminum aids avoid getting too hot, therefore enhancing performance and lengthening tool longevity. In addition, the lightweight nature of aluminum enhances its thermal buildings, making it an excellent option for portable technology. As makers progressively prioritize efficiency and power effectiveness, light weight aluminum's function in thermal management ends up being a lot more considerable, leading to its growing fostering in contemporary electronic styles. This pattern emphasizes aluminum's relevance in consumer electronic devices innovation.

Marine Sector: Corrosion Resistance in Harsh Atmospheres

Deterioration resistance is a critical aspect in the marine market, where tools and frameworks are consistently revealed to severe saltwater atmospheres. Light weight aluminum, especially in its alloy types, uses substantial advantages hereof. Its natural oxide layer offers a protective barrier that avoids rust, making it excellent for vessels, anchors, and other marine applications.

Marine-grade aluminum alloys, such as 5083 and 6061, are especially developed to withstand the corrosive effects of saltwater and climatic conditions. These alloys not just stand up to corrosion however additionally maintain structural honesty and strength with time. Applications range from hulls and superstructures of ships to parts in offshore platforms.

The light-weight nature of aluminum more improves its viability, allowing enhanced gas effectiveness and convenience of handling - Aluminum Casting. As the marine sector remains to concentrate on toughness and performance, light weight aluminum remains an essential material option for resisting rust in demanding marine settings

Advancements in Aluminum Spreading Techniques

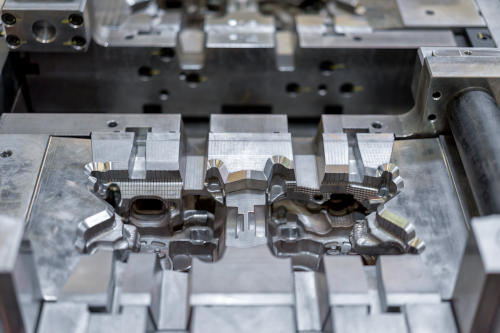

While conventional light weight aluminum casting approaches have actually served the sector well, recent innovations are here are the findings transforming the landscape of light weight aluminum manufacturing. Strategies such as 3D printing of cores and molds are acquiring traction, enabling rapid prototyping and minimized lead times. This advancement allows manufacturers to produce complex geometries that were formerly hard to achieve with traditional spreading techniques. Furthermore, innovations in die-casting technology, including using high-pressure die-casting (HPDC), have actually boosted the accuracy and surface area finish of cast light weight aluminum components, leading to enhanced efficiency in numerous applications.

Furthermore, the fostering of financial investment casting has actually allowed for greater design freedom and minimized material waste. Casting Foundry. Technologies in alloy structures are also significant, as they enhance mechanical residential or commercial properties and rust resistance. On the whole, these developments not just simplify manufacturing procedures however likewise add to even more sustainable methods within the light weight aluminum foundry sector, making it adaptable to the progressing demands of modern-day manufacturing

Future Patterns in Light Weight Aluminum Foundry Manufacturing

The future of light weight aluminum shop manufacturing is positioned for substantial makeover via automation, boosting performance and accuracy in making procedures. Sustainable methods are progressively ending up being a priority, as foundries look for to decrease their ecological effect while meeting growing governing needs. Furthermore, developments in alloy advancement will enable the production of more powerful, lighter products customized for diverse applications, driving development in the industry.

Automation in Foundry Processes

Sustainable Manufacturing Practices

A growing emphasis on sustainable manufacturing practices is improving the future of light weight aluminum shop manufacturing. Market leaders are significantly embracing energy-efficient innovations and recycling campaigns to decrease waste and minimize carbon footprints. Using recycled aluminum substantially reduces energy consumption compared to key light weight aluminum production, making it a preferred selection for eco mindful manufacturers. On top of that, innovative spreading strategies are being established to improve product efficiency and lower emissions. Companies are additionally spending in renewable resource resources, such as solar and wind, to power their procedures sustainably. aluminum foundry. By incorporating these techniques, the aluminum factory market not only satisfies regulatory requirements yet additionally replies to customer need for greener items, ultimately leading the means for a more lasting production landscape

Advanced Alloy Growth

Innovations in light weight aluminum alloy development are established to play a substantial function in the future of shop production, particularly as sustainability and performance demands rise. The sector is significantly concentrating on producing high-strength, lightweight alloys that can hold up against severe problems while decreasing environmental effect. Researchers are checking out cutting-edge structures, such as aluminum-lithium and aluminum-scandium alloys, which promise enhanced mechanical homes and lowered weight. Furthermore, the integration of innovative manufacturing strategies, content including additive manufacturing and accuracy casting, enables more facility geometries and minimized product waste. As governing stress and customer choices shift in the direction of greener alternatives, the development of energy-efficient and recyclable alloys will be important. The future landscape of aluminum shop manufacturing hinges on these improvements in alloy modern technology.

Frequently Asked Concerns

What Are the Ecological Effects of Light Weight Aluminum Factory Workflow?

Aluminum shop procedures can lead to substantial ecological effects, including greenhouse gas emissions, power usage, and waste generation. Additionally, inappropriate management of pollutants might cause soil and water contamination, influencing neighborhood ecological communities and communities.

Just How Does Light Weight Aluminum Recycling Affect Foundry Processes?

Light weight aluminum recycling improves shop processes by giving a cost-efficient raw material, lowering energy usage and exhausts. This lasting practice boosts performance, decreases waste, and supports the circular economic situation, profiting both manufacturers and the atmosphere.

What Precaution Are Executed in Aluminum Foundries?

Light weight aluminum shops implement various security procedures, consisting of personal safety tools, proper air flow systems, regular security training, fire avoidance protocols, and equipment upkeep treatments to decrease hazards and ensure a secure workplace for all employees.

How Do Foundries Guarantee Top Quality Control in Aluminum Casting?

Factories assure quality assurance in light weight aluminum casting with strenuous material examinations, accurate temperature level monitoring, standard treatments, and normal screening of cast products. These steps assist maintain uniformity, decrease problems, and meet market specs properly.

What Are the Cost Consider Aluminum Factory Production?

Price factors in aluminum foundry production consist of resources rates, power intake, labor prices, tools upkeep, and overhead expenditures. In addition, manufacturing quantity and intricacy of styles considerably influence overall manufacturing costs and earnings.

As the automobile industry increasingly focuses on light-weight products to improve gas performance and efficiency, light weight aluminum factories have become essential contributors to manufacturing procedures. Aluminum foundries play a substantial role in the aerospace field, where the demand for light-weight materials is critical for enhancing gas efficiency and efficiency in airplane. Furthermore, developments in light weight aluminum foundry strategies have actually improved the precision of aluminum elements, ensuring they fulfill strict structure codes. While conventional light weight aluminum casting approaches have served the sector well, current innovations are transforming the landscape of light weight aluminum production. The use of recycled light weight aluminum considerably reduces power usage contrasted to primary light weight aluminum manufacturing, making it a preferred choice for ecologically mindful makers.